Understanding the Colors of Electrical Wires: Guide to Electrical Safety

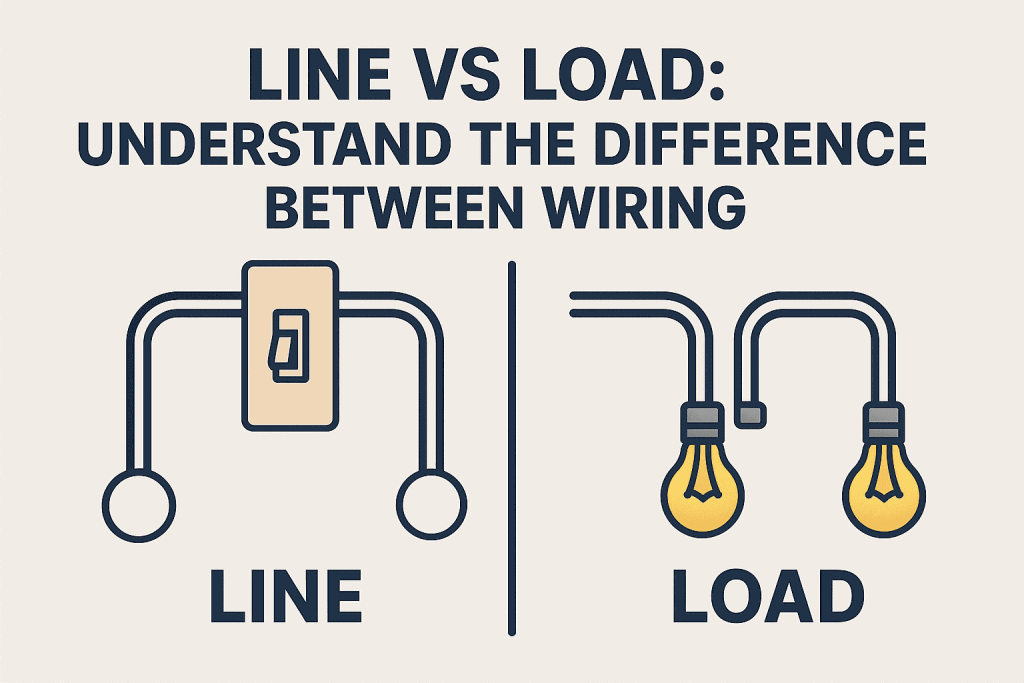

Electricity powers nearly every aspect of our lives—from the lights in our homes to the appliances we depend on daily. Yet, behind the walls, under the floors, and in the ceilings, a complex system of electrical wires ensures everything runs smoothly. One of the most crucial elements in this system is color coding. If you’ve ever opened an outlet box or seen a group of wires, you might have noticed that they’re not all the same color. These colors are not chosen at random—they serve a vital role in identifying the function and safety of each wire. At Brea Electric, our licensed electricians stress the importance of understanding these wire colors before attempting any electrical work. In this blog, we’ll break down the color codes for electrical wires, their meanings, and why it’s essential to understand them—even if you’re not an electrician. Why Wire Color Coding Matters Color coding in electrical wiring isn’t just a convenience—it’s a safety standard. These codes are regulated by the National Electrical Code (NEC) in the United States to help electricians and homeowners: Mishandling the wrong wire can result in serious injuries, property damage, or even fatal electrocution. That’s why understanding wire colors is one of the most important safety basics in any electrical project. Common Electrical Wire Colors and Their Meanings Let’s explore the most commonly used wire colors in residential and commercial wiring systems across the U.S., what each represents, and where you’re likely to encounter them. 1. Black Wires — The Standard Hot Wire Meaning: Hot or LiveFunction: Carries electrical current from the power source to outlets or fixturesUsed In: Switch legs, outlets, lights, appliances Black wires are perhaps the most universally recognized in electrical systems. These are live wires that carry electricity from the service panel to the device in use. When dealing with black wires, always assume they are energized, even when switches are off. Safety Tip: Never attempt to touch or modify a black wire unless the power is completely turned off at the breaker panel. 2. Red Wires — Secondary Hot Wire Meaning: Secondary HotFunction: Used for interconnection between smoke detectors, or in 220-volt setupsUsed In: Three-way switches, hardwired smoke detectors, split-phase systems Red wires are also hot wires, often used in switch legs or to link hardwired smoke detectors so that if one alarm goes off, all do. They’re commonly seen in setups requiring multiple hot wires, like 240V outlets or three-way switch configurations. 3. White Wires — Neutral Meaning: NeutralFunction: Carries electricity back to the breaker panelUsed In: Almost all residential and commercial circuits While white wires are neutral, they still carry current—just in the opposite direction. After the electricity flows through a device, it returns through the white neutral wire to the electrical panel, completing the circuit. Important Note: In some rare cases, a white wire may be tagged with black or red electrical tape to indicate it’s being used as a hot wire—especially in switch loops. Always double-check. 4. Green Wires — Ground Meaning: GroundFunction: Provides a path for electrical current to reduce the risk of electrocutionUsed In: All grounded electrical systems Green wires are essential for electrical safety. They connect your devices and appliances to the earth, ensuring that stray currents safely dissipate in the event of a short circuit. They are never used for live current. 5. Bare Copper Wires — Ground (Alternative) In many homes, especially older ones, you’ll find bare copper wires serving the same function as green ones. These uninsulated wires are typically ground wires and serve the same safety purpose. 6. Blue and Yellow Wires — Travelers and Switch Legs Blue WiresMeaning: Traveler wire or hot wireFunction: Used in three- or four-way switch configurationsUsed In: Complex switch setups, lighting controls Yellow WiresMeaning: Switch legFunction: Transfers power to a light or fanUsed In: Switch loops, ceiling fans, structural wiring While not as common in everyday wiring, blue and yellow wires are used for more complex control systems. If your home has multiple switches controlling a single light fixture, these are the colors you’re likely to see. Color Coding in 240V and Three-Phase Circuits In residential applications, most wiring is for 120V single-phase, but in some cases—especially in garages, workshops, or commercial buildings—you’ll see 240V or three-phase wiring. Here are common color codes: Wire Type Color Hot (L1) Black Hot (L2) Red Hot (L3 – if used) Blue Neutral White Ground Green or Bare Copper When working with three-phase power, the color codes can vary slightly by region or specific use, so always consult a professional electrician like those at Brea Electric for proper guidance. Color Coding for Low Voltage Wiring (Thermostats, Doorbells, etc.) Low-voltage systems like doorbells, thermostats, security systems, and audio wiring may follow different conventions depending on the manufacturer or installer. These wires typically operate at less than 50 volts, but they should still be handled with care and proper understanding. Color Misconceptions & Regional Variations Although the NEC provides standards for wire colors in the U.S., some older homes or installations by non-certified individuals may not follow proper codes. If you’re uncertain about any wiring, it’s safest to consult a certified electrician from Brea Electric, serving California residents with professionalism and care for over 40 years. Line vs Load: Understand the diffrence between wiring – CLICK HERE Common Mistakes to Avoid When Working with Electrical Wiring When to Call a Licensed Electrician Working with electrical systems isn’t a typical DIY project. If you encounter any of the following, it’s time to call in a professional: The team at Brea Electric is always ready to help homeowners and businesses ensure that their electrical systems are safe, efficient, and up to code. Final Thoughts: Wire Colors Are More Than Just Visual Cues Understanding the colors of electrical wires can help you stay informed and safe—especially when dealing with basic home electrical inspections or upgrades. However, always remember that color codes are only part of the safety equation. The safest and most reliable way to handle any electrical

Understanding the Colors of Electrical Wires: Guide to Electrical Safety Read More »